(2 pm. – promoted by ek hornbeck)

One point that constantly comes up when the push to 100% sustainable, renewable power is raised is the problem that “renewable power sources cannot be relied on to deliver power 24/7”. This is a talking point pushed by the propagandists for Big Coal in particular, since the biggest challenge to their long term existence as an industry in the United States is the threat that we begin to get serious about tapping our abundant Wind Power resources on-shore in the Great Plains and Mountain West and off-shore on the Great Lakes and Atlantic Coast. When the wind is blowing, it substantially undermines the market for fossil-fuel “Baseload Power” (see (The Myth of Baseload Power).

One point that constantly comes up when the push to 100% sustainable, renewable power is raised is the problem that “renewable power sources cannot be relied on to deliver power 24/7”. This is a talking point pushed by the propagandists for Big Coal in particular, since the biggest challenge to their long term existence as an industry in the United States is the threat that we begin to get serious about tapping our abundant Wind Power resources on-shore in the Great Plains and Mountain West and off-shore on the Great Lakes and Atlantic Coast. When the wind is blowing, it substantially undermines the market for fossil-fuel “Baseload Power” (see (The Myth of Baseload Power).

After all, consider two scenarios, one in which a power source replaces half of the power from coal by replacing half the power, all of the time, and a second, in which a power source replaces all of the power, half the time. The second is a greater threat to coal-fired power, since it swings the advantage to natural-gas fired power. Natural-gas fired power is presently killing off coal-fired plant construction, and a sufficiently large and volatile supply of Windpower would make that permanent.

So of course Big Coal spreads the idea that all sustainable power is volatile and if its volatile, it can’t provide all of our power.

This present essay is not about answering that argument rationally. That was the topic of The Myth of Baseload Power. This present essay is about attacking the political foundations of Big Coal.

After all, propaganda about “Clean Coal” and spreading the myth that there is this special kind of power called Baseload power that sustainable energy has impact because of the political influence of Big Coal in Coal Country. And this is a particularly pernicious influence, since it runs on a cycle of:

- Coal production provides export base employment in an area.

- Coal production also diverts a majority of the value-added from production out of the production area;.

- which helps assure that the Coal production areas are, on average, lower income economies than elsewhere in the country;

- which undermines the area’s capability to diversify its economy, helping to assure that the jobs in Coal production are valued jobs in the local area, which increases local political support for “supporting” Big Coal;

- And with a less diversified economy, there are fewer resources available to contest the political power and influence of Big Coal.

- With its political power, Big Coal ensures that the rules in place continue to ensure that a majority of value-added is drained out of the production area

This essay is about undermining that political power at its base, by creating more jobs from a direct rival to coal production than Big Coal can offer. Once a better deal is made available, with more employment, more value-added circulating locally, and no destruction of people’s health through the hauling up of poisonous by-products from underground, the foundation on which Big Coal’s political power is based is in a position to fracture.

What is that direct rival to coal production? Bio-coal production.

What Is Bio-Coal?

What is Bio-Coal? According to Baltic Bioenergy and Industrial Biocoal,

What is Bio-Coal? According to Baltic Bioenergy and Industrial Biocoal,

Biocoal is a solid fuel made from biomass by heating it in an inert atmosphere. The result is either charcoal, or if the process temperature is mild, a product called torrefied wood. Charcoal and torrefied wood can be called by common name biocoal.

Compared to untreated biomass biocoal has several advantages. It has high energy content, uniform properties and low moisture content. Biocoal can be used in coal fired power plants, which have difficulties with other biomass based fuels, such as wood chips.

If biocoal raw material originates from sustainably managed forests, the product is CO2 neutral. The growing new tree generation captures the same amount of CO2 from atmosphere that is released in the manufacture and combustion of biocoal.

Note that this comes primarily from Finland and Latvia, which are presently wood product exporting countries, and the description here is a bit specialized. In particular, the Bio-Coal technology they are looking to employ is production in an inert atmosphere. However, here in the United States, a different type of Bio-Coal production process has been developed in Hawaii at the Hawaii Natural Energy Institute: flash carbonization:

Research at the University of Hawaii (UH) has led to the discovery of the Flash Carbonization™ process that quickly and efficiently produces biocarbon (i.e., charcoal) from biomass. This process involves the ignition of a flash fire at elevated pressure in a packed bed of biomass. Because of the elevated pressure, the fire quickly spreads through the bed, triggering the transformation of biomass to biocarbon. Fixed-carbon yields of up to 100% of the theoretical limit have been achieved in as little as 20 or 30 minutes. (By contrast, conventional charcoal-making technologies typically produce charcoal with carbon yields of much less than 80% of the theoretical limit and take from 8 hours to several days.) Feedstocks have included woods (e.g., leucaena, eucalyptus, and oak), agricultural byproducts (e.g., macadamia nutshells, corncobs, and pineapple chop), moist green wastes (e.g., wood sawdust and Christmas tree chips), various invasive species (e.g., strawberry guava), and synthetic materials (e.g., shredded automobile tires).

This process captures the gases emitted in the process, which are medium quality thermal gases containing some of the heat generated in the process as well as hydrogen, which can be burned to co-generate electricity. The overall energy efficiency of the process is a result of the combination of effective conversion of carbon to biocoal and co-generation of electricity from the exhaust gases. Just after I first reported on their work in Daily Kos (10 Jan 2007), Harris and Hill (2007) assessed flash carbonization in Carbon-Negative Primary Production: Role of Biocarbon and Challenges for Organics in Aotearoa/New Zealand, Journal of Organic Systems – Vol.2 No.2, 2007:

The flashcarbonization process, first described by Antal (2004), revolutionises charcoal production. At elevated pressures (1MPa) and temperature (400° C) the process is extremely fast, is catalysed by water, is highly exothermic [heat-creating, not heat-consuming], and the yield of fixed-carbon attains the theoretical yield at thermochemical equilibrium. The latter is achieved by holding the pyrolytic vapours captive and in contact with the solid products, where they are converted into biocarbon (Antal et al. 2000). Biomass can be converted to biocarbon in less than 30 minutes with the generation of substantial excess energy over what is required for ignition. By completely altering the economics of biocarbon production, flash-carbonization is a critical step in developing an economically viable biocarbon fuel-cell (Antal et al. 2003, Nunoura et al. 2007).

For our purposes, one of the revolutionary features of flash carbonization is that it is both a weight-losing process and a batch process.

What is the important of weight-losing processes? Weight-losing processes imply that the transportation of the product is substantially more efficient than the transportation of the feedstock. This is a factor that creates an economic advantage for locating the production closer to the feedstock source, rather than closer to the consumer of the final product. Indeed, if the biocoal is briquetted, and if production is placed in existing coal-producing areas, the biocoal can be transported using the existing dirty-coal transport system.

What is the importance of batch production? Batch production processes are easier to operate intermittently, and easier to economically “scale down” than continuous production processes. Combined with the weight-losing nature of the process, this means that if the feedstock is located in dirty-coal producing areas, both the employment from growing the feedstock and the employment from producing the bio-coal may be located in dirty-coal production areas. It also means that the co-generation of power from batch production of bio-coal can be timed to coincide with the periods when electricity is most valuable.

Obstacles to use of Bio-Coal as a Sustainable Power Source

Biofuels Digest gave an excellent summary of the obstacles to the greater use of bio-coal in power generation in this country in October 2011:

Biofuels Digest gave an excellent summary of the obstacles to the greater use of bio-coal in power generation in this country in October 2011:

The primary issue to be overcome is the cost of thermal coal vs. the expected cost of bio-coal. It is a fact that thermal coal is still a very economic fuel and it is highly probable that the premium that will have to be paid for bio-coal will more than likely be of significance for many years to come.

Another issue is the fact that bio-coal availability will be in short supply for the next several years and the price will more than likely remain high due to supply-demand imbalances. Considering that commercial scale torrefaction processes are just now being commissioned, bio-coal plants are few and far between and the technologies being used are still evolving. Although the cost effectiveness of processing biomass into bio-coal may improve, it is expected that it will take time to add sufficient bio-coal capacity and improve efficiency.

Further, there will be limits in availability of woody biomass for use in making bio-fuels, and if the use of bio-coal increases dramatically, it could affect the cost of acquiring woody biomass as a bio-coal feedstock. There are only a limited number of locations in which timber harvesting takes place in the US and those that use forest products for competing uses, such as paper and lumber used in construction and manufactured wood products, are expected to keep woody biomass prices high.

However, note that these problems are primarily under the premise of no effective government action to promote the use of biocoal. First, the low cost of coal is a financial comparison, not an economic comparison, since, as the Renewable Resource Resource Laboratory in Hawaii notes:

Note 1: because of its high content of mercury, sulfur, and other noxious elements and compounds, the price of coal is not comparable to the other (relatively clean) fuels listed. To be comparable, the price of coal should include the necessary cleanup of these noxious materials (especially mercury) at the outlet of the powerplant. Unfortunately, reliable data on the cleanup costs are not easily available. Also, a carbon tax will impact the price of coal more than other fuels.

Full-cost pricing of coal will inevitably narrow or eliminate any price differentials with bio-coal, since plant feedstocks do not result in high mercury content carbon. Also, while dirty-coal is among the highest carbon emission fossil fuel, the use of plant feedstocks grown in a sustainable way results in low-carbon, carbon-neutral or even carbon-negative fuel (confer with Harris and Hill (2007 [pdf]) on carbon negative power when accounting for use of bio-char as fertilizer and carbon sequestration by root systems of perennial plants).

The second problem is clearly resolved if there is a government program to ensure sufficient feedstock supply to correspond with government regulations of carbon emissions of coal plants that make it preferable to use the biocoal that is available.

And the third problem assumes the most dramatically that there is no effective government policy to promote biocoal. Our existing biomass production is not aimed at producing biomass, it is aimed at producing something else. We cut down whole trees in our timber industry because the point of the process is to produce wood and paper pulp. If our aim is to produce biomass, we would do the same as Henry VIII (of the many wives and two surviving daughters, father of Elizabeth I, the first sovereign queen of England), when looking to guarantee sufficient charcoal for England’s ironmaking industry. We would produce coppice (Wikipedia machine).

As I wrote the last time I reported on Bio-Coal:

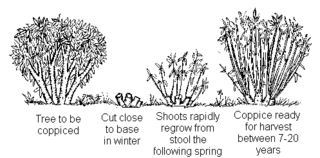

What is coppice? Coppice is harvesting a tree for perennial production by cutting it down near to the roots, allowing the base and root system to remain in place so that new shoots can emerge in the following year. Coppice is harvested in a rotation, on a cycle that varies from one type of tree to the next.

And, of course, if we harvest coppice from hill or mountain along the contours of the terrain, the retention of the tree roots systems combines with the natural terracing effect of contour farming to retain both soil and rainfall runoff far better than clearfell timbering.

Henry the VIII introduced regulations that required a certain number of large trees, “standards”, to grow in the midst of the coppice woodlot. This was, of course, a “strategic defense” reserve, at the time, since the Royal Navy needed timber to make their Wooden Ships.

Today, the most pressing strategic issue we face is avoiding the destruction of the ecosystem services that we rely upon for our survival. And so we probably should steal a trick from the House of Tudor, and incorporate a similar system in a contour-coppicing system. This would involve rewarding producers for allocating, say, 10% of land to ridgeline and mountaintop forest reserves, and 10% of contours to production of larger timbers.

Side-Note: A Particularly American Coppice-System

If you are following the main argument, you can skip this part, but I did not want to leave this out entirely.

If you are following the main argument, you can skip this part, but I did not want to leave this out entirely.

One particularly appealing coppice tree crop is hybrid Asian-American chestnut. At one time as many as one in four trees in Appalachia were Sweet Chestnut trees, which yielded a strong, naturally pest-resistant timber, tannin for leather production, and sweet chestnuts for sale to roasters and to pig farmers. A fungus imported from Asia over a century ago devastated the eastern Sweet Chestnut forests. Hybrid breeding with fungus-resistant Asian chestnuts produced blight resistant trees … but there was a catch:

Unfortunately, Chinese and Japanese chestnuts tend to be shorter. As scientists for the U.S. Department of Agriculture(USDA) discovered when they started breeding hybrids in the 1930s, many more genes than the few that govern resistance also cross over. Initially the hybrids grew like gangbusters and appeared to resist the blight. But when they stopped growing after a few decades, the USDA scientists realized they had a problem. The trees were only 50 to 60 feet tall.

Hopes for the tree seemed stymied by a Catch-22: Blight-resistant trees require Asian genes, yet Asian genes produce a tree with neither the height nor the hardiness to survive the fierce forest competition for sunlight. In 1960 the USDA shut down its chestnut-breeding program and the tree seemed consigned to oblivion.

But it should be obvious that as a coppice tree, the fact that the tree stops growing in twenty years is entirely beside the point, because if you have not coppiced it yet, you coppice it then. This is, indeed, another example of how our agricultural knowledge is focused upon the end products we are trying to produce: a tree that is a failure as a timber tree in sustainable mixed woodland timber production is not necessarily a failure as a biomass production tree.

Indeed, the key element in selection of the hybrid for coppice is not the height of the tree after fifty years, but rather the quality of the chestnut produced. What made the Sweet Chestnut such an enduring part of 19th century Appalachian rural incomes was the annual income from the collection and sale of the chestnuts. Indeed, it was said that you could produce as much pork on an acre of Sweet Chestnut as on an acre of corn … and the acre of Sweet Chestnut did not have to be flat.

The same income flow would make the hybrid Asian/Sweet Chesnut a valuable coppice feedstock, provided hybrid strains can be developed that produce nuts that closely resemble the original Sweet Chestnut in quality as both food, after roasting, and as animal feed.

OK, now back to the main argument.

A Policy Package to Cut Big Coal Off At The Knees

Remember, the main aim here is to establish a sustainable, renewable energy source that can grow to have the political clout to take down Big Coal. So getting it going requires first a political break-through in coal-producing state such as Ohio or Pennsylvania, and then rapidly moving in a “first 100 days” way to setting the ball rolling. Once the program is in place, the first aim is to create immediate beneficiaries in locales where Big Coal typically turns to when making an appeal that “they are stealing your jobs (and, silently, more to the point that large part of our profits that come from shifting costs onto the public).

Remember, the main aim here is to establish a sustainable, renewable energy source that can grow to have the political clout to take down Big Coal. So getting it going requires first a political break-through in coal-producing state such as Ohio or Pennsylvania, and then rapidly moving in a “first 100 days” way to setting the ball rolling. Once the program is in place, the first aim is to create immediate beneficiaries in locales where Big Coal typically turns to when making an appeal that “they are stealing your jobs (and, silently, more to the point that large part of our profits that come from shifting costs onto the public).

So the first stage is a carbon tax on fixed point electricity sources that directly funds the establishment of sustainable bio-coal production in the state, and the establishment of a support price for the production of coppice feedstock and targeted agricultural extension for the developing of coppiced feedstock production “in those counties determined to offer the strongest income gains to owners of agricultural land and strongest benefits in reducing soil erosion and improving surface water quality”.

There’s no need to explicitly target Appalachian counties in order to target Appalachian counties, since the strongest gains to local agricultural incomes will be in the Appalachian countries, the strongest benefits to reducing soil erosion will be from contour-coppicing of hilly terrain, and the greatest improvement in surface water quality will come from contour-coppicing hilly terrain.

Unlike timber production, contour-coppicing supports a relatively stable annual output from a given hillside. If the coppice interval is 12-20 years (such as Sweet Chesnut coppice in the UK today), you harvest one in 12 to one in 20 contour rows per years.

Note that in production of contour-coppice for biocoal feedstock, you do not have to wait until the first coppiced wood is harvested to sell biocoal feedstock, since the clearing of hillside contours for coppiced wood production itself produces bio-coal feedstock. If the land is heavily degraded, this might be brush and scrub rather than valuable timber, but brush and scrub are still useful as biocoal feedstocks.

If the land is heavily degraded, some of the biocoal output should be replaced in the hillside as bio-char to promote establishment of healthy root systems by the new coppice wood crop being plants, and this provides an essential part of the income-support program. The price support program involves a guaranteed offer to buy biocoal at a given price in order to sequester the carbon by using it as biochar in an approved in-state agricultural use.

Now, anywhere in Coal Country where bio-coal batch production equipment is located, anyone owning marginal land that wishes to take advantage of the new market for bio-coal feedstock can have their coppiced wood production plans approved by the state agricultural extension office, and then they are selling biocoal feedstock as they clear their marginal land for production of coppiced wood, in order for the bio-coal to either be bought at a state-guaranteed, coal-power-plant subsidized price to be produced into biochar that they can use to inexpensively improve the quality of their land, or else bought at a higher price by the coal power plants themselves to be used as low-net-carbon bio-coal.

You will notice that I have not said a word about what carbon tax rate to place on fixed point electricity generators. The answer is, “enough to get the program up and running”. We have seen in Iowa what happens when a dirty bio-fuel, corn-starch ethanol, becomes important enough to be an appreciable source of farmer’s incomes. Now consider what will happen to the politics of the issue when you channel carbon tax incomes from coal-fired electricity (and, to a lesser extent, natural-gas-fired electricity) into production of biomass on marginal hilly lands in rural Applachian counties.

And this is a fossil fuel producer divide-and-conquer policy. Sure this taxes production of electricity from natural gas. But production of electricity from natural gas uses substantially less carbon per Kilowatt, on a fuel-content basis. So it actually provides a short to medium term benefit to Natural Gas producers, since over the short to medium term, Coal is their primary rival, and they actually benefit from pushing volatile sustainable, renewable energy production up into the 20%-40% range of total energy supply, since their share of fossil fuel produced power is likely to increase more rapidly than the total share of fossil fuel produced power declines.

Why Ohio or Pennsylvania, rather than Kentucky or West Virginia

My notional target for this policy has been either Ohio or Pennsylvania after some Democratic breakthrough in one of these states. Why Ohio or Pennsylvania, rather than Kentucky or West Virginia? (Image: Athens, Ohio, in the heart of Southeastern Ohio Appalachian counties)

My notional target for this policy has been either Ohio or Pennsylvania after some Democratic breakthrough in one of these states. Why Ohio or Pennsylvania, rather than Kentucky or West Virginia? (Image: Athens, Ohio, in the heart of Southeastern Ohio Appalachian counties)

Bear in mind that in Ohio and Pennsylvania, the political clout of rural Appalachian counties comes from entering into fights between Democratic, largely big city urban and inner suburban interests and Republican outer-suburban and small urban area interests, and tilting the balance. This is normally to the benefit of suburban Republican interests, but it is on occasion in the service of Democratic interests, especially when it involves populist economic issues.

Now consider the impact of the influence of Big Coal in a number of these rural Appalachian counties is neutralized, or even reversed. Republican big-city outer suburban and smaller urban area interests are faced with a choice between allowing alliance between large city urban and inner suburban interests and the interests of rural Appalachian counties, or between flipping on mineral coal versus bio-coal and making bio-coal into a bipartisan consensus, so they can hope to continue to divert the rural Appalachian counties from their economic interests with the shiny bauble of social issue controversy.

Further, while rural Appalachian counties are one substantial target for biocoal feedstock, flash carbonization is a quite flexible process and can use quite a range of feedstocks. You can produce bio-coal from corn stover, from perennial grasses such as switchgrass, and from a wide range of waste products, including discarded tires and sewage. Different degrees of moisture content will generate a different mix of bio-coal and co-generated electricity from the flammable exhaust gas, so would likely involve batch producers specialized to particular types of inputs, but the basic process is far from finicky about its choice of feedstock.

Therefore, while the agricultural extension would be focused on marginal hilly land, especially already degraded hilly land, the funds subsidizing establishment of production of biocoal can be distributed across the state. In addition to generating rural Appalachian agricultural incomes, it can help reduce costs of waste disposal for large urban areas. So in states like Ohio or Pennsylvania, those interests that emerge in favor of bio-coal production can find allies across the state.

The ultimate goal is, however, for the bio-coal production to become so popular in these Appalachian “border states” that it swings the Federal balance of political power in this issue, and leads to Federal programs that brings this production into the Appalachian heartland.

This Policy Approach as part of a Pedal to the Metal Climate Policy Package

Over the past two weeks (part 1, and part 2), I have discussed the concept of “front-runner” policies in a Pedal to the Metal Climate Policy package.

Over the past two weeks (part 1, and part 2), I have discussed the concept of “front-runner” policies in a Pedal to the Metal Climate Policy package.

The policy as described above seems more incrementalist. (1) Get one state to adopt a policy that gets the ball rolling. (2) Allow the political support for the policy to grow. (3) Take advantage of the success of the policy to take it nationwide.

I haven’t abandoned consideration of Pedal to the Metal Climate Policies … far from it. However, the role of bio-coal in a 100% sustainable, renewable power production system is intrinsically not a front-runner role. The US can get to 40% sustainable electrical power with 20% Wind, 10% solar, 6% hydropower and 4% assorted other sustainable power with our existing dispatchable hydropower resource and with some modest investment in long distance power transmission for both stranded renewable power (more resource than power consumption in the region) and cross-haul renewable power (from region A to B when region A is producing strongly, from B to A when B is producing strongly).

However, as is clear from a closer examination of the Australian case considered in The Myth of Baseload Power, dispatchable renewable power becomes more critical as a nation approaches a 100% sustainable, renewable electricity supply. In the Australian case, it is the substantial Outback solar resource which can be cost-effectively exploited with Concentrated Solar Thermal (CSP) power that bridges an important part of that gap, since rather than building a generating plant with the capacity for the total heat produced at the solar peak, CSP power collects heat into a heat storage medium and then generates power by drawing heat out of that storage medium. The extra cost of that middle stop is more than repaid by the much better economic efficiency is using a higher average capacity of the generating plant, which can deliver power when it is most economically valuable over the following half day.

Given Australia’s CSP resource relative to its population, cross-haul between Australian States plus the available hydropower resource is quite enough to bridge the gap between demand and supply for the volatile Wind and Photo-Voltaic Solar power supplies, even with a 100% sustainable, renewable power supply.

The US high quality CSP resource is nowhere near as abundant relative to our population, which is around 15x Australia’s population. Therefore a similar system tailored to US conditions will require either substantially more storage, or substantially more new dispatchable power sources.

With my suspicion of promised Silver Bullet solutions, I believe that bio-coal can play an important role in bridging this gap, but the strongest benefit may be in bio-coal power generation in combination with power storage facilities.

That is, the cost of power storage depends critically on how long you have to store the power. Power storage for a day’s power gap is substantially cheaper than power storage for a week’s power gap, which is substantially cheaper than power storage for seasonal power gaps, such as the Luddington Pumped Storage Power Plant.

Since conventional hydropower represents a fixed annual budget of renewable power, it should be reserved for meeting the seasonal power gaps that are hardest to meet with stored power. On the flip side, the first power gaps to address with stored power are power gaps on the scale of a day’s supply.

And if our system is equipped with dispatchable stored power on the scale of a day’s supply, bio-coal can play an invaluable role, since power production from bio-coal can be started up based on an expectation of a gap. There is always some uncertainty as to the timing and size of the gap, but it can be started up to be delivering power before the gap arrives, and rather than wasting power with spinning reserve while waiting for the gap to show up, the excess power can be fed into the day-scale power storage. As the system hits peak power demand, the bio-coal power production would narrow the gap with the balance coming from the day-scale power storage. And then as the peak power demand passes, the bio-coal would continue to produce power to replenish the power in day-scale power storage.

This day-scale power storage is a grid resource, not a resource dedicated to the bio-coal power producer, so it would also be available to use to feed excess Wind Power supply at night into peak demands the following day and excess hydropower production from run-of-river hydropower or excess cogenerated power from industrial processes during third shift production.

Indeed, current pumped hydropower technology offers this day-scale storage production. We do not presently have it in substantial amounts because with a primarily fossil-fuel fired power system, we don’t need very much of it. But if it becomes a strategic resource, we only need to establish effective pricing mechanisms to reward investment in the infrastructure, and we can have substantial supplies.

Indeed, for free-standing pumped hydro, with a reservoir on top and bottom, the two factors that determine the power that can be stored is the size of the reservoirs and the rise between the bottom-end reservoir and the top-end reservoir. So given the kind of transcontinental Electricity Superhighways that are part of the Steel Interstate system describe in the Sunday Train two weeks ago, this form of day-scale energy storage offers yet another sustainable energy opportunity for Appalachia.

Conversations, Considerations and Contemplations

As you can tell, I really do think bio-coal is not just a politically strategic renewable energy resource, but also a strategic part of getting from 50% to 100% sustainable renewable power. However, the time has come to find out what you think.

So now, as always, rather looking for some overarching conclusion, I now open the floor to the comments of those reading.

If you have an issue on some other area of sustainable transport or sustainable energy production, please feel free to start a new main comment. To avoid confusing me, given my tendency to filter comments through the topic of this week’s Sunday Train, feel free to use the shorthand “NT:” in the subject line when introducing this kind of new topic.

And if you have a topic in sustainable transport or energy that you want me to take a look at in the coming month, be sure to include that as well.

1 comments

Author

“Nothing’s more important / than a hole in the ground”